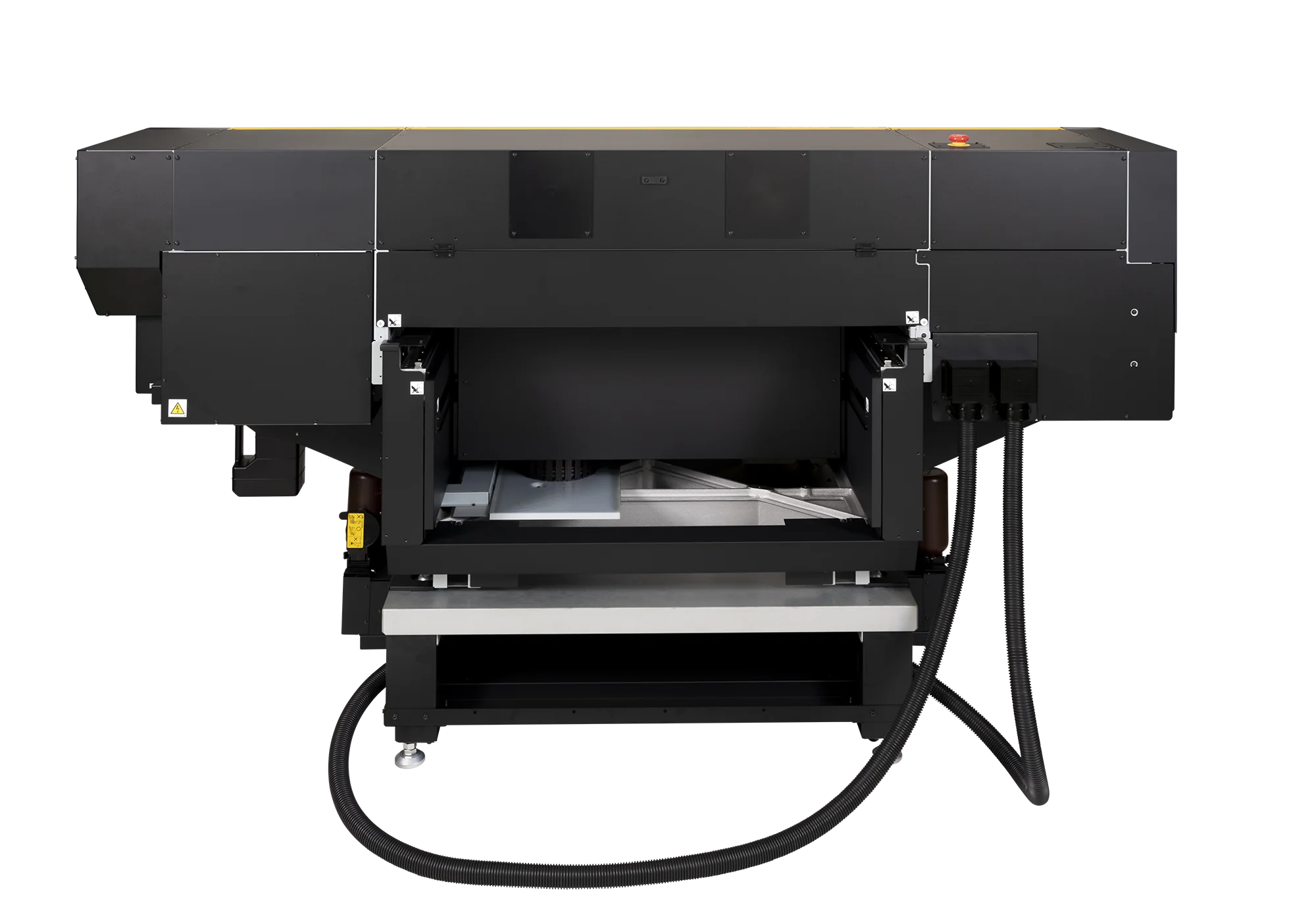

Mimaki UJF-7151 plus II e

Mimaki UJF-7151 plus II e

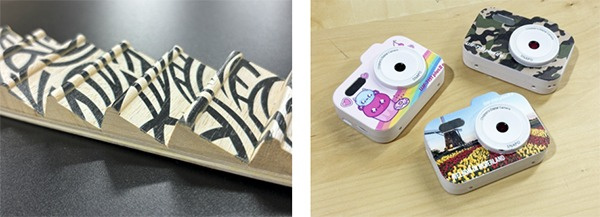

The proliferation of digital printing has normalized short-run, multi-variety production in custom goods printing sector, such as smartphone cases, promotional items, and character goods. In the industrial printing sector, inkjet printers capable of stable printing on diverse materials like metal and resin are increasingly being adopted.

Description

1. Industry-leading precision and image quality in the industrial printer market

Achieves industry-leading print accuracy through a robust chassis structure and high-precision position control. Excels in industrial printing applications such as dials and control panels. Furthermore, its high resolution of up to 1,800 dpi, combined with the use of light cyan and light magenta inks in addition to standard four-color printing, reproduces delicate color tones like skin tones and landscapes with natural and smooth results.

Examples of high-precision printing applications: dials, control panels

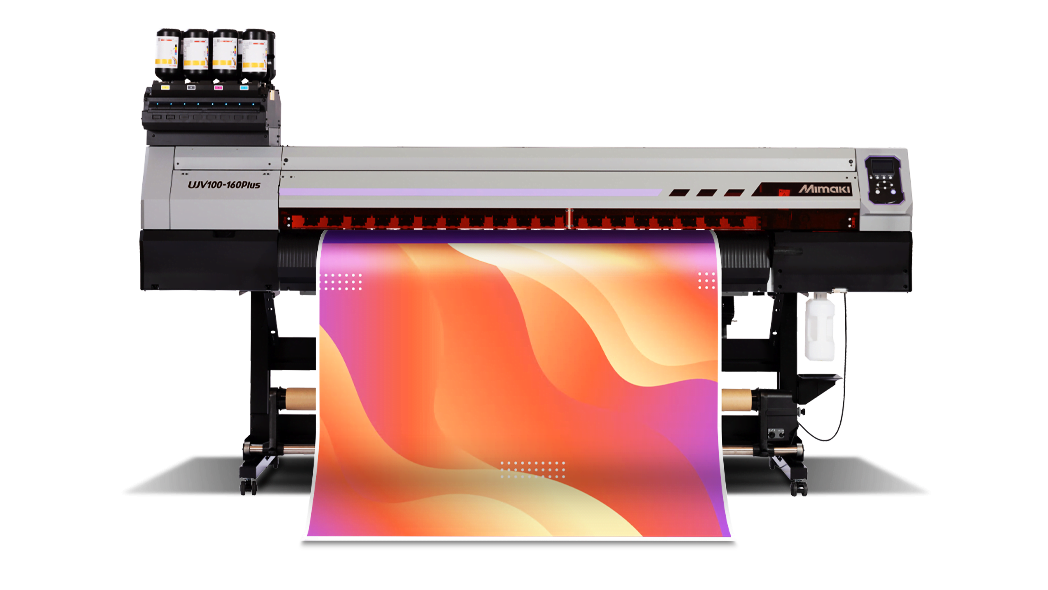

2. High-speed printing enables efficient production without printing plates

In practical mode*1, it can produce 19 sheets per hour (710mm x 510mm). The plate-free inkjet method eliminates plate creation and setup change processes, offering flexible support for short-run, multi-variety production.

*1. CMYK ink set, when using 600×600 dpi 6-pass printing

Express the item’s premium feel through its texture

3. Expand three-dimensional expression with raised printing up to 5mm thick

With a maximum ink layering of up to 5mm—significantly exceeding conventional models—it enables embossed effects and three-dimensional texture expression. This greatly expands the range of possibilities for goods production and decorative design expression.

Reproduce designs down to the deepest parts of materials with height differences and steps

5. Enhancing print productivity for industrial materials through accelerated primer*3 application

Equipped with printable primer ink, it significantly reduces application time compared to conventional models. This dramatically increases printing speed onto industrial materials requiring primer treatment—such as acrylic, glass, and metal*4 — by approximately 3.7 times.

*3. Pre-treatment agent for enhancing ink adhesion

*4. Metal… refers to stainless steel, aluminum, steel, and brass.

6. Ink-saving feature that reduces running costs with simple operation

With just two clicks, achieve up to approximately 42% ink reduction while maintaining color balance. Even without specialized knowledge, you can reduce running costs.

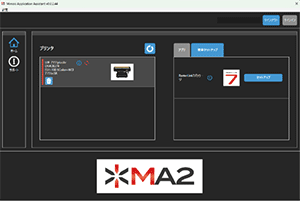

Furthermore, to support our customers’ production from both hardware and software perspectives, we are simultaneously releasing the new software integration management tool “Mimaki Application Assistant (MA2)”. MA2 displays a list of all software compatible with your Mimaki printer and enables you to manage it in an optimal state at all times. This allows you to seamlessly utilize product updates and feature enhancements, maximizing the convenience of our continuously evolving software.

Through providing integrated hardware and software solutions, we will contribute to enhancing our customers’ production quality and improving operational efficiency.

MA2 Interface Screen