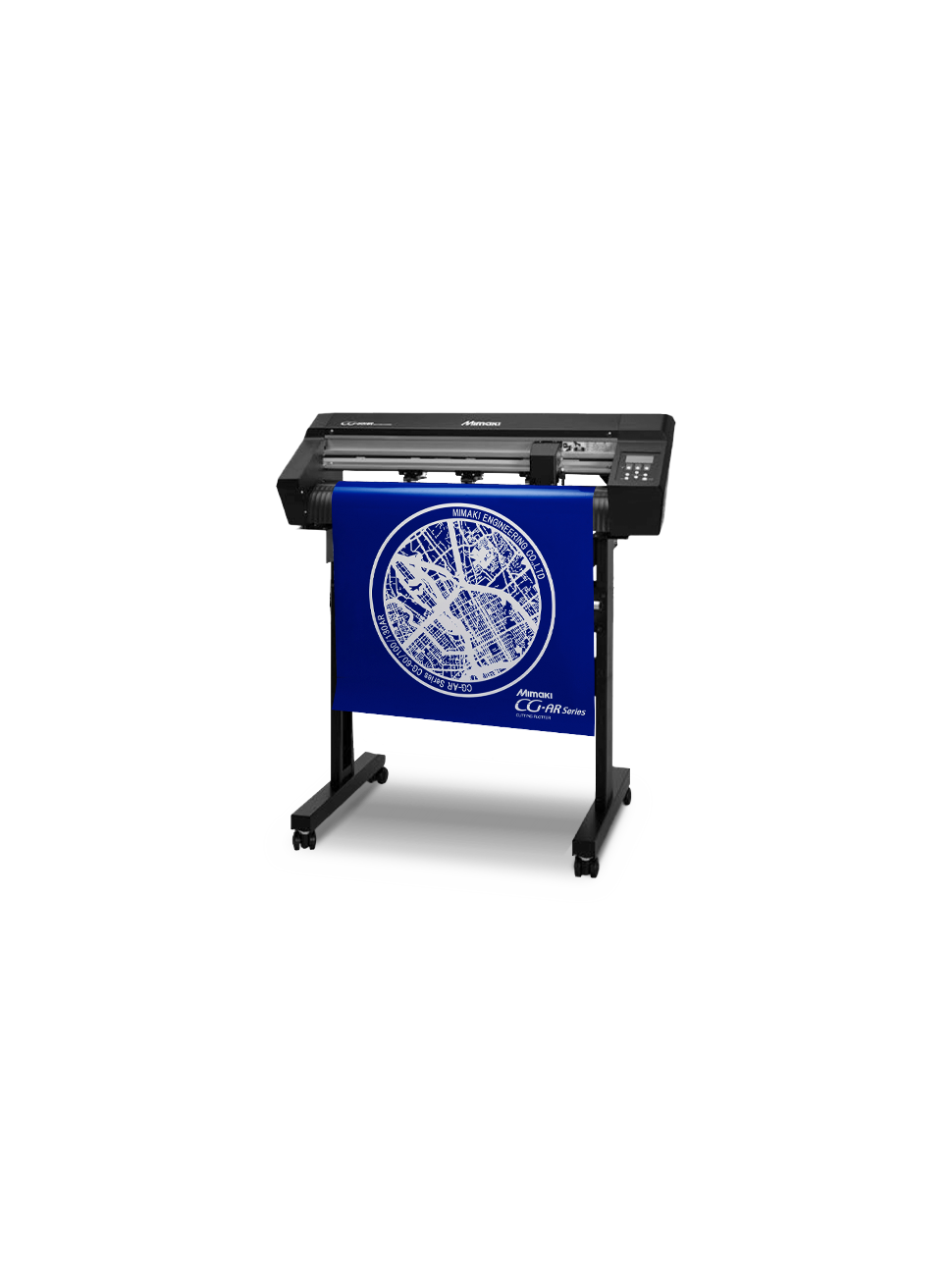

CG-60AR

Mimaki CG-60AR

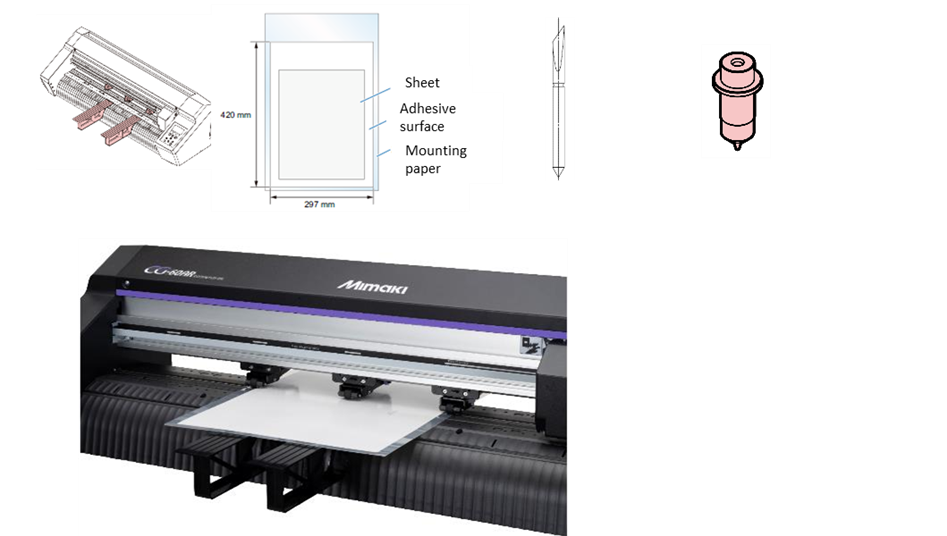

CG-60AR Roll-to-roll and

sheet-fed cutting plotter

The new CG-60AR cutting plotter builds on the strong heritage of its predecessor and comes with intuitive new features and optimized specifications. With the unique ID-Cut function, increased pressure and improved precision, it delivers reliable and precise cutting when working flawlessly with Mimaki printers.

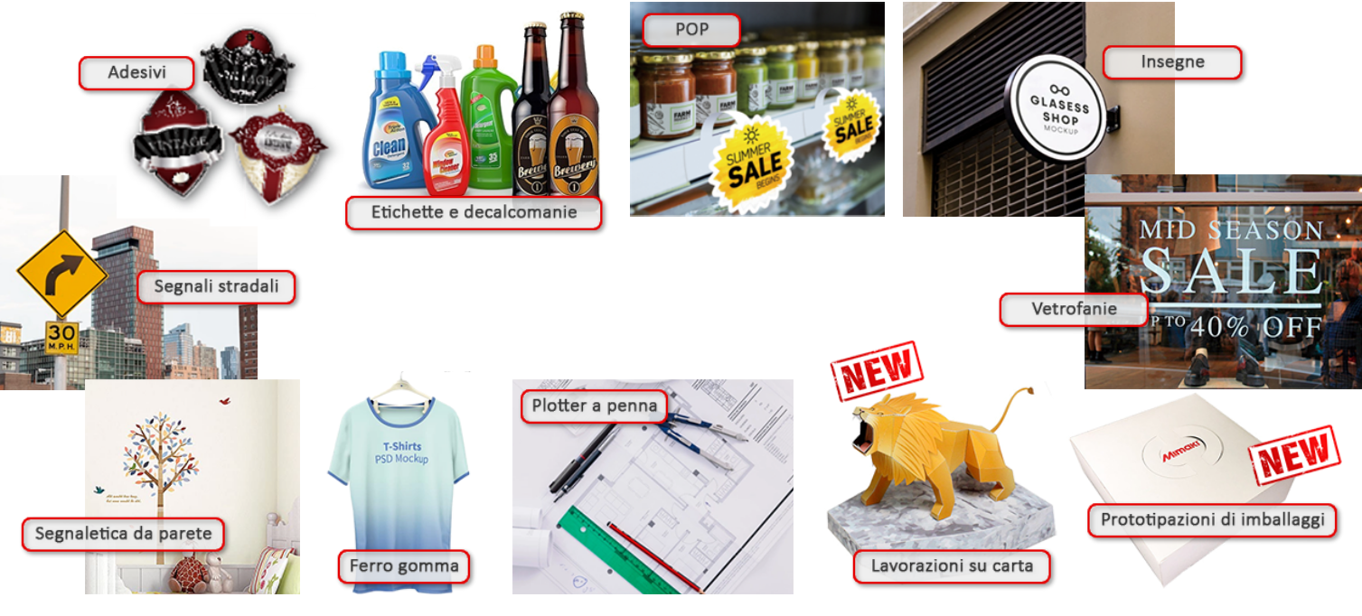

MULTIFUNCTIONAL CUTTING PLOTTER WITH MAXIMUM VERSATILITY

The CG-AR series of cutting plotters has the highest cutting pressure in the segment for the use of a wider range of materials and offers new options for complete cutting of cardboard.

Thanks to the ID CUT function the work process is automatic, limiting errors and ensuring material savings.

Mimaki CG-60AR

ADVANTAGES

For even more confidence, our products are GREENGUARD GOLD certified.

GREENGUARD GOLD certified products meet strict standards regarding low volatile organic compound emissions and reinforce that the product is suitable for use in places such as schools and health centers, without polluting indoor air quality.

Mimaki CG-60AR

SPECIFICATIONS

Mimaki CG-60AR

CORE TECHNOLOGY

This cutting plotter features Mimaki Core Technologies that deliver the best quality, maximum productivity and minimize risks that can delay production. See below for a list of core technologies included in the CG-AR Series.

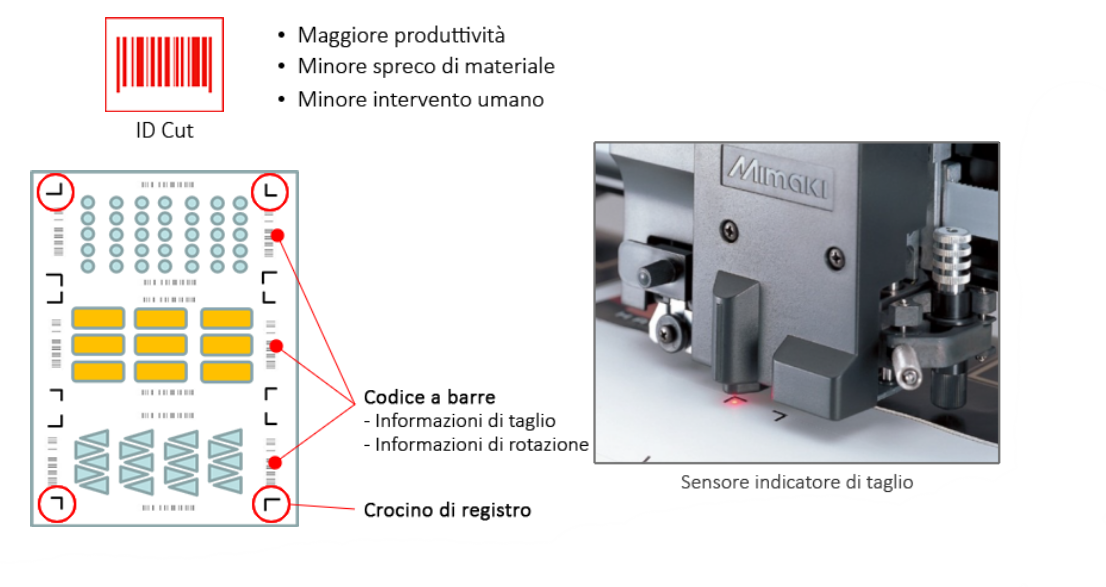

ID Cut

ID Cut is a Mimaki solution that prints cutting data in the form of a barcode between the registration marks of the images. On the cutting plotter, the barcode and registration marks are scanned by an optical sensor and cutting starts accordingly, without the need to send the cutting data separately, reducing human intervention.

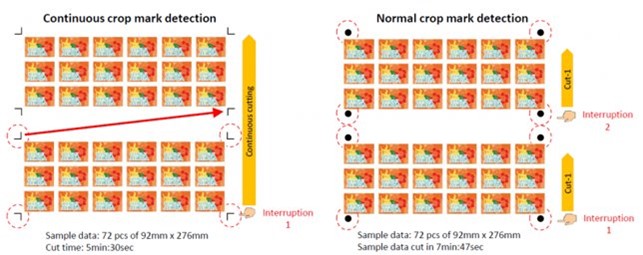

Crop Mark DetectioN

This technology looks for consecutive crop marks and realigns the media accordingly, thus achieving highly accurate cutting on each image.

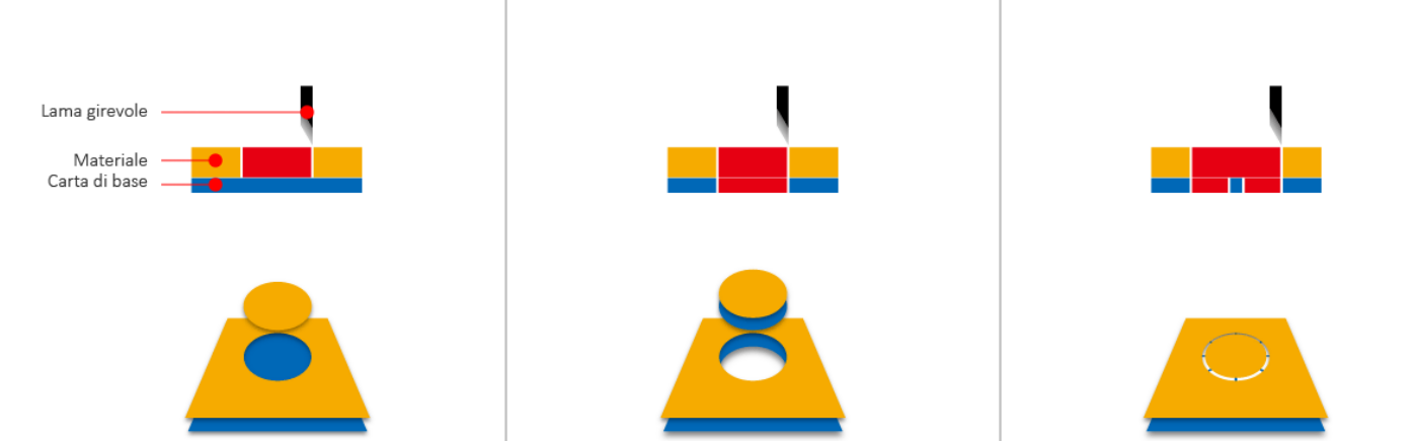

Half Cut

This technology combines “die cut” and “kiss cut” into a single contour, leaving a few connection points that hold the image in place after cutting into the media roll.

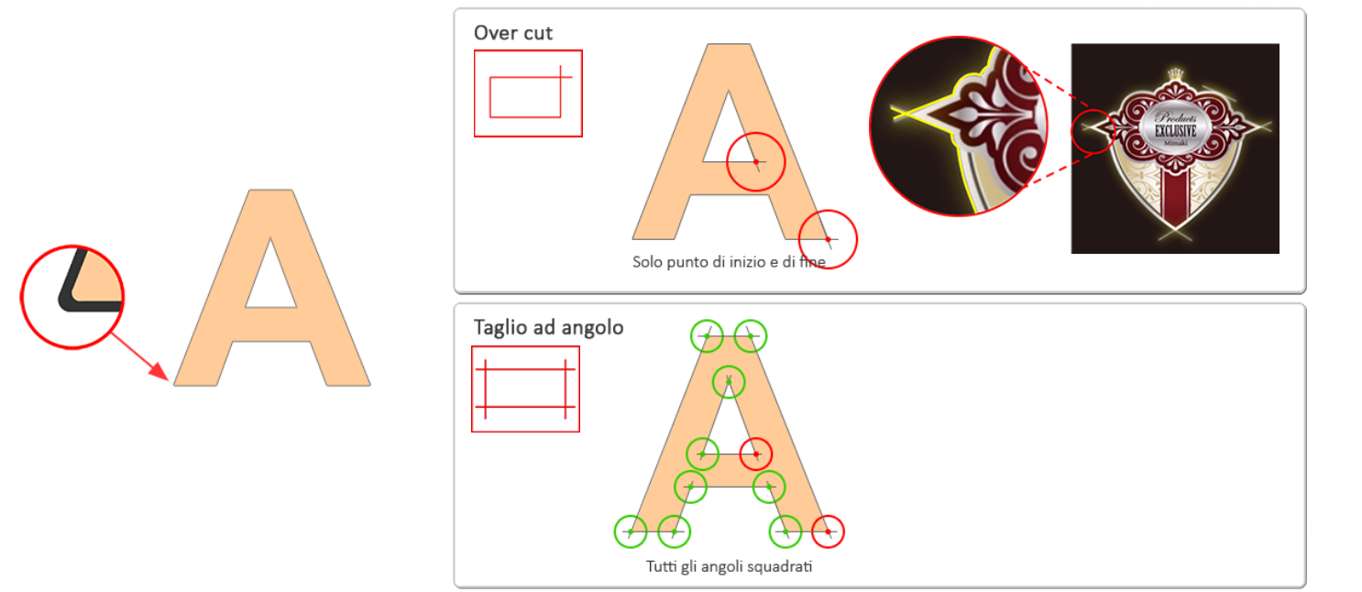

Over Cut

This technology cuts a perfect intersection at the beginning and end points in a single contour, ensuring easy vinyl removal.

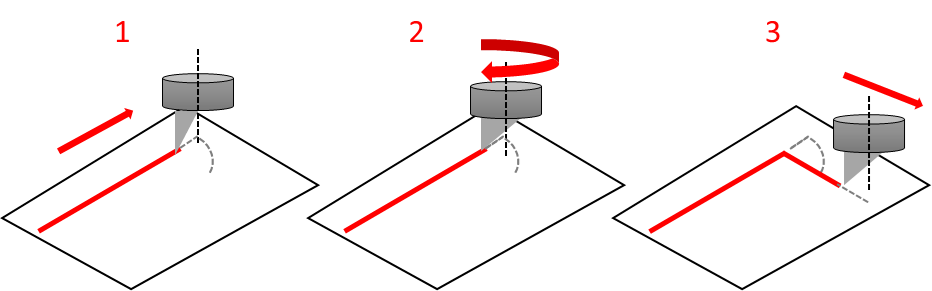

Corner Cut

This technology creates the perfect intersection of all sharp corners in a single contour, ensuring the ideal cut.