SPEEDY 100 CROSS: THE INDUSTRIAL DIODE LASER PLOTTER FOR HIGH-PRECISION MARKING AND CUTTING

The Speedy 100 cross is the ideal choice for industrial parts marking and impresses with razor-sharp detail on metals and plastics. It enables large-area marking up to 610 x 305 mm (24 x 12 in) and is ideal for small to medium throughput volumes.

With a speed of 2.8 m/s (110 ips) and 40 watts laser power, it also excels in the field of personalization and when used in schools and universities. Its versatility allows the processing of a wide range of materials and future applications. It also masters the cutting of thin organic materials such as paper, cardboard and wood with ease.

Speedy 100 cross – The first industrial-grade diode laser plotter for marking and cutting.

Industrial diode laser plotter for marking and cutting.

The Speedy 100 cross has been developed for companies in the digital production sector that require maximum flexibility and precision for laser markings in the area of traceability. Its working area of up to 610 x 305 mm (24 x 12 in) is ideal for marking large components as well as small to medium-sized series. Thanks to its low maintenance requirements, the Speedy 100 cross offers reliable and user-friendly operation. It also offers an excellent price-performance ratio, ensuring a solid ROI.

Advantages of the Speedy 100 cross

Versatile, cost-effective laser marking for a wide range of materials

Safely and cost-effectively mark parts up to 610 x 305 mm (24 x 12 in), including metals and organic materials, without additional protective equipment.

Even more efficient with Ruby® laser software

Manage orders, machines and users independently and securely with Ruby’s user-friendly, fully functional interface.

Starter pack with diode-friendly materials

Contains tested diode-friendly Trotec materials including laser parameters in the Ruby® laser software.

Service packages for optimized laser operation

Benefit from personalized technical support and smart maintenance with seamless monitoring for efficient, reliable workflows.

Perché le esigenze individuali

richiedono una consulenza individuale.

Contatta Bompan ora

Precision and efficiency for your production.

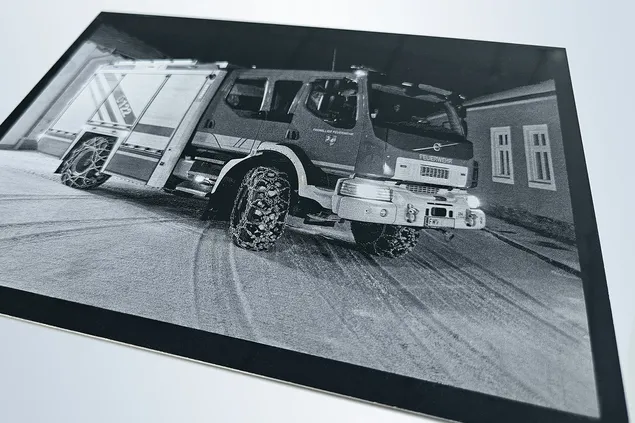

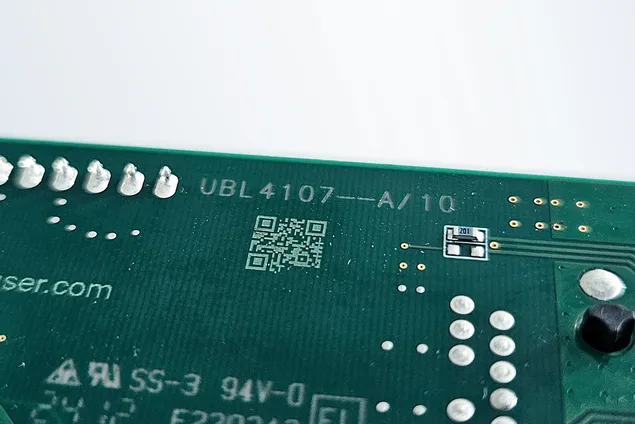

The Speedy 100 cross enables razor-sharp marking and is ideal for marking QR codes, serial numbers or detailed graphics on metal or plastic components, type plates or printed circuit boards. Durable marking at a low cost ensures seamless and tamper-proof traceability.

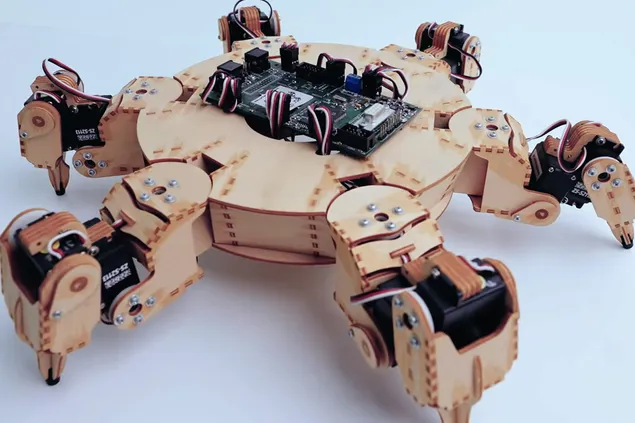

Versatility and a wide range of applications.

Easily engrave or cut a wide variety of materials. The Speedy 100 cross is perfect for a wide range of industries and applications, including industrial marking, product personalization and education. The outstanding precision in material processing opens up unique possibilities, for example in photo engraving, to create detailed and fascinating images.

Functions, options and accessories of Speedy 100 cross.

Sono supportati tutti i programmi grafici standard.

Trotec’s Atmos extraction systems remove dust and gas efficiently and are therefore the ideal addition to Speedy Laser.

InPack technology

Protects sensitive machine components (axis, laser head, optics, lenses) from dirt and dust and ensures years of trouble-free operation, even under heavy use.

Rotary engraving attachment

Engrave cylindrical, round or conical objects with the highest precision.

Touchscreen

Use the computer for work preparation; the touch panel is intended for editing the order list.

Autofocus

With a simple keystroke, the processing table automatically moves to the correct position.

Air assist

The integrated pump protects the lens by preventing dust from adhering to it.

Optimal footprint

A perfect balance between machine size and working area, offering more flexibility and taking up less space.

CE certificate

Our machines meet all official requirements and ensure safe operation.

Honeycomb cutting table

Especially for cutting flat materials where minimal back reflection is desired.

Temperature sensor

If the temperature in the engraving chamber exceeds a critical level, the laser emits a warning signal to the operator.

Laser pointer

The laser pointer indicates the exact point of impact of the laser beam on the material with a red dot.

Un confronto delle aree di lavoro

dei nostri convenienti laser cutter.

Laser efficiency with Ruby® software:

seamless transition from design to

finished lasered product.

Ruby® enables efficient workflows through seamless connectivity, allowing users to work simultaneously anytime, anywhere. This increases productivity and optimizes workflows by allowing files to be uploaded from programs like Illustrator without having the program, saving time, money and hassle. Automating processes, such as importing CSV files to automatically populate templates, speeds production and standardizes results. An open API enables integration with ERP and MES systems for automated job creation and tracking, reducing downtime through optimized planning and queuing. Ruby® also supports mass customization and variable data engraving with industrial databases.

Create graphic

Send design to Ruby®

Fulfil an order with Speedy

Get the perfect product

Parts marking

Direct marking of metals for data plates, components, tools, printed circuit boards.

Respond quickly to customer requests and reduce dependence on suppliers by insourcing laser marking and cutting parts up to 610 x 305 mm (24 x 12 in).

Make your production planning more effective. Reduce lead times and ensure consistent quality. Improve efficiency by separating job preparation and production with Ruby® laser software.

Streamline the entire process from design to final product. Manage multiple projects simultaneously. Reduce errors, save time and increase productivity.

Personalization

Process a wide variety of materials directly with the laser. Expand your range of services and meet a variety of customer needs. Improve efficiency by processing any customer file from anywhere on the network with Ruby® laser software.

Seamless data processing and collaboration. Optimize workflow and reduce bottlenecks. Faster project completion. Open up new business opportunities and stay competitive.

Produce more in less time. Less maintenance means fewer interruptions and lower operating costs. Maximize your ROI.

Reduce per-part costs with faster engraving and low maintenance costs compared to hobbyist lasers.

Schools and universities

Eliminate the need for multiple devices. Save space and reduce equipment costs. Cost-effective solution for educational institutions. Increase productivity per teaching hour by independently managing design, job preparation and laser operation with Ruby® laser software.

User-friendly interface for teachers and students. Efficient and engaging learning environment. Promote creativity and innovation. Make every class period more productive and enjoyable.

More projects in one class period. More hands-on experience for students. Improved learning outcomes. Optimize budget and floor space with a low-maintenance laser marking and cutting machine.

What materials can you engrave

or cut with Speedy 100 cross?

| Materials | Engraving/Marking | Cutting |

| Metal | ✔ | |

| Acrylic transparent | ||

| Acrylic colored | ✔ | ✔ |

| Glass transparent | ||

| Glass colored | ✔ | |

| Mirror | ✔ | |

| Ceramics | ✔ | |

| Plastic sheets | ✔ | ✔ |

| Plastics | ✔ | ✔ |

| Paper white | ✔ | ✔ |

| Paper colored | ✔ | ✔ |

| Cardboard | ✔ | ✔ |

| Leather | ✔ | ✔ |

| Fabrics | ✔ | ✔ |

| Wood | ✔ | ✔ |

| Cork | ✔ | ✔ |

| Food | ✔ | |

| Stone | ✔ |