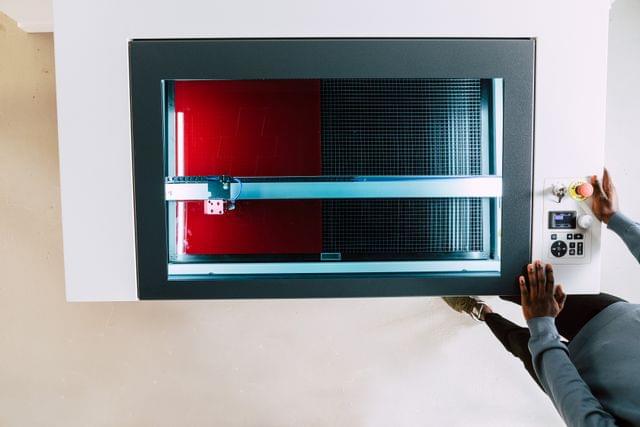

EVERYTHING A LASER CUTTER NEEDS

The Q Series: The Laser Cutter You Can’t Do Without

The Q Series laser cutters are packed with all the key strengths of Trotec required for efficient laser cutting, setting new standards in the industry. With a working area of up to 1300 x 900 mm and a maximum laser power of 120 watts, these machines support both cutting and engraving on a wide variety of materials.

They can be used to process acrylic and wood (up to 15 mm thick), fabrics, paper or cardboard for signage, crafts, models, or decorative items. Q Series laser machines are reliable solutions for production.

Because you’re more efficient with a laser cutter.

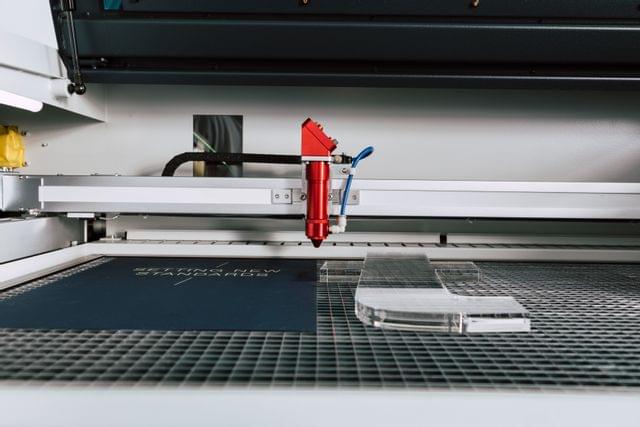

How is the productivity promise fulfilled? By using Trotec core technology: The drive concept and OptiMotionTM provide the speed, the red Trotec laser head enables fast yet precise laser processing. The ultra-compact, lightweight design integrates the most important functions in the smallest of spaces. The InPack TechnologyTM: protects all sensitive components of the mid-range laser cutter from dust.

Because you can work reliably and for a long time with the laser cutter.

The Q500 Laser Cutter is equipped with a powerful DC CO2 laser for fast laser cutting, a CeramiCore® RF CO2 laser for high-quality laser engraving or both. The innovative and patented CeramiCore® laser source concept stands for reliability, durability and high engraving quality. The resonator of the laser source, where the laser beam is generated, is 100% ceramic. One investment – two tools.

Because you can work intuitively with the mid-range laser cutter.

Ruby®, the design software for the laser machine, ensures a smooth workflow. Create graphic, photo and text elements and make adjustments quickly thanks to the integrated workflow. With software that is also a graphics and laser program. And a user interface that inspires. Ruby® connects all your laser machines in one network, locally or on the go.

Because individual requirements

require individual advice.

Contact with Bompan now

8x faster cutting.

Move along the curves as if on rails. Our unique OptiMotion™ path control automatically adapts the cutting speed to the geometry. Achieve the best contour accuracy with the highest productivity when cutting. This is an unbeatable advantage, particularly with thin materials such as foils or vector marking.

3.2 sec.

cutting job with Q

27 sec.

cutting job with comparable lasers

Everything you need for laser cutting.

Cut and engrave a variety of materials. Acrylic, wood, textiles, paper or cardboard up to 15 mm material thickness. The Q series combines all Trotec virtues for efficient laser cutting – everything you need for laser cutting.

15 mm

max. material thickness

> 20

materials

1 investment, 2 tools.

Achieve perfect results when cutting as well as engraving. The built-in DC CO2 laser sources for fast cutting and the CeramiCore® RF CO2 for high-quality engraving.

ONE

laser system

TWO

laser sources

MULTIPLE USERS

Work together as a team with different roles and permissions. For example, operators cannot adjust laser parameters, they can only assign them. Students cannot start laser jobs without a teacher. Graphics pre-press and laser production work together seamlessly. Multiple users – 1 laser machine.

4

simple steps

∞

USERS

Engrave twice as fast.

Engrave twice as fast as inexpensive entry-level laser machines. A sign that takes 10 minutes on an entry-level laser machine can be engraved in less than 5 minutes with the Q series. 2m per second and 2G maximum engraving speed make this possible.

2x

faster engraving

2G

acceleration

TROTEC Q SERIES