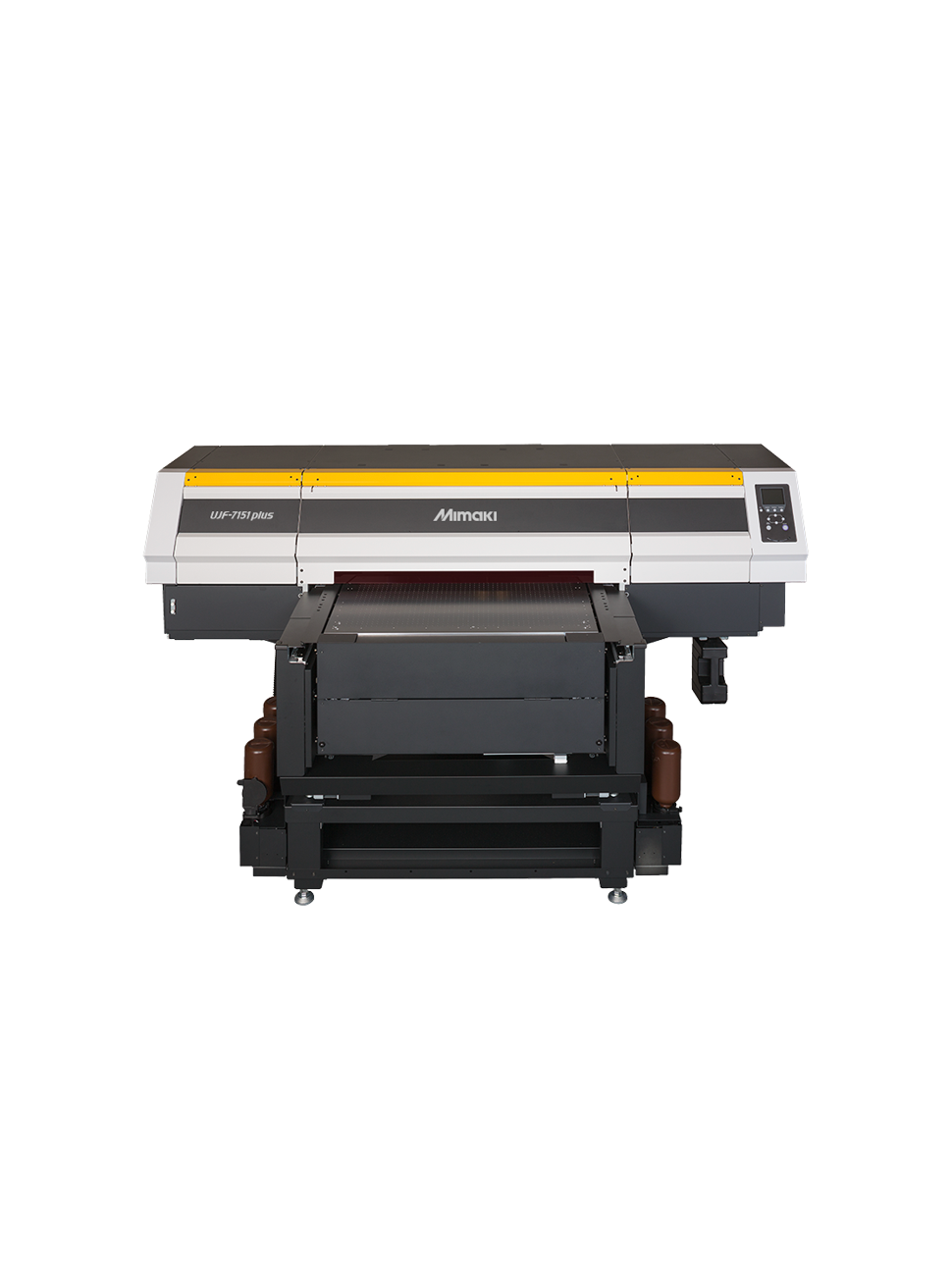

UJF-7151 PLUS

Mimaki UJF-7151 Plus

ULTRA-MODERN DESKTOP

UV LED PRINTER

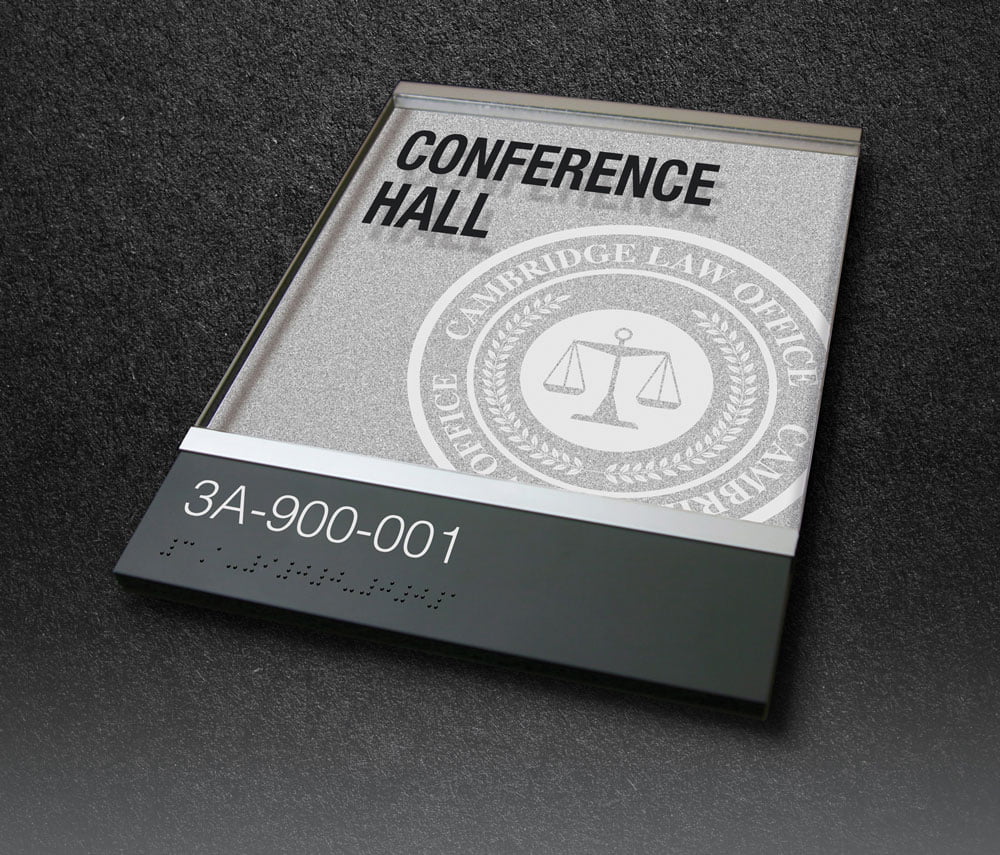

UV-LED direct-to-object printing technology, the UJF-7151 plus reaffirms Mimaki’s market dominance in this ever-growing sector. The UJF-7151 plus uses cutting-edge technology to provide a highly reliable digital alternative to traditional screen printing operations.

The Mimaki UV LED flatbed UJF-7151 brings increased productivity and ease of use to direct-to-object printing. Available in 710mm x 510mm format, this new model built on Mimaki’s expertise offers spectacular creativity and unlimited opportunities that can print on virtually any material.

UV LED FLATBED PRINTER WITH ABSOLUTE MICRO PRECISION

UJF-7151 plus is Mimaki’s high precision and very high quality UV LED printer, also ideal for use in the industrial sector. Thanks to the latest generation technologies that characterize it, it offers an advantageous and reliable digital alternative to traditional printing processes.

Mimaki UJF-7151 Plus

ADVANTAGES

For even more confidence, our products are GREENGUARD GOLD certified.

GREENGUARD GOLD certified products meet strict standards regarding low volatile organic compound emissions and reinforce that the product is suitable for use in places such as schools and health centers, without polluting indoor air quality.

Mimaki UJF-7151 Plus

SPECIFICATIONS

Mimaki UJF-7151 Plus

CORE TECHNOLOGY

This printer features Mimaki Core Technologies that deliver the best print quality, maximum productivity and reduced exposure to

hazards that can delay production. See below for a list of features.

Productivity and Convenience

PRINT QUALITY

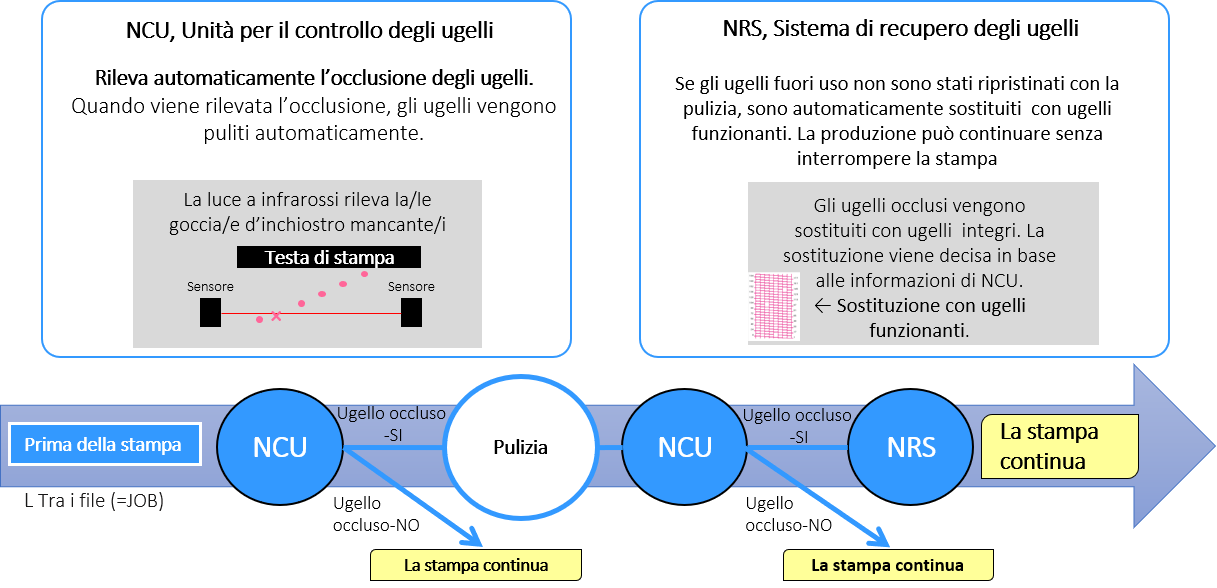

Nozzle Check Unit

This technology controls the printing nozzles and automatically activates a series of recovery functions, ensuring printing quality and avoiding waste.

Nozzle Recovery System

This technology automatically assigns operational nozzles when an interruption is detected, giving you the assurance that your production and costs will not be affected.

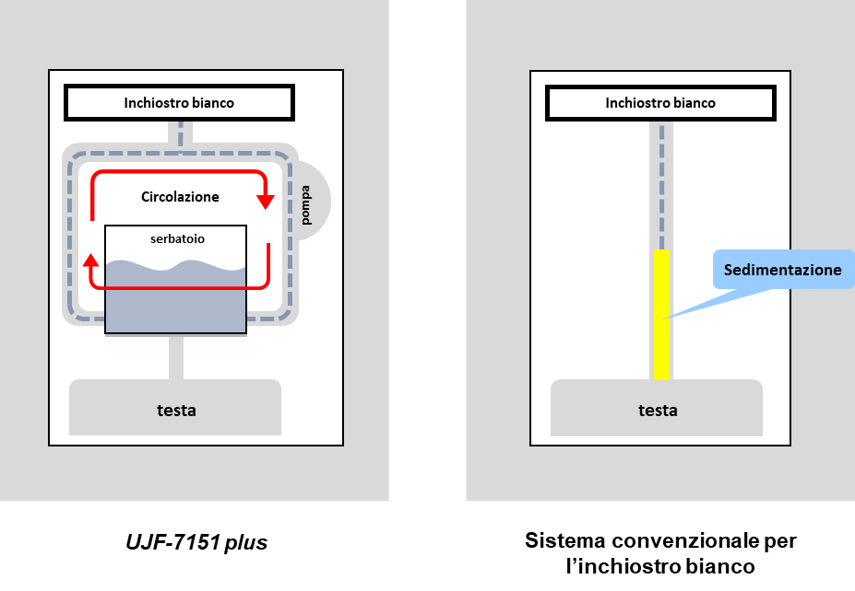

Mimaki Circulation Technology

MCT is a function that prevents pigment sedimentation by periodically circulating the ink in its ink channel, reducing maintenance costs and increasing productivity.

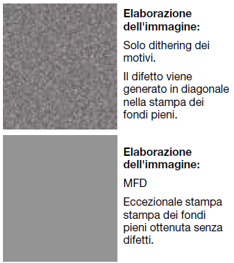

Mimaki Advanced Pass System

Mimaki’s exclusive Advanced Pass System technology uses an advanced algorithm that reduces banding, allowing high print quality even at higher speeds.

Waveform Control

WFC automatically switches the signal to the print head when printing conditions change and ensures consistent image quality.

Variable Dot Technology

VDT is a feature of the piezo print head that allows the creation of ink droplets of different sizes, allowing for smoother gradations and greater detail.