SWJ-320EA

Mimaki SWJ-320EA

The best large format printer

to win a competitive market

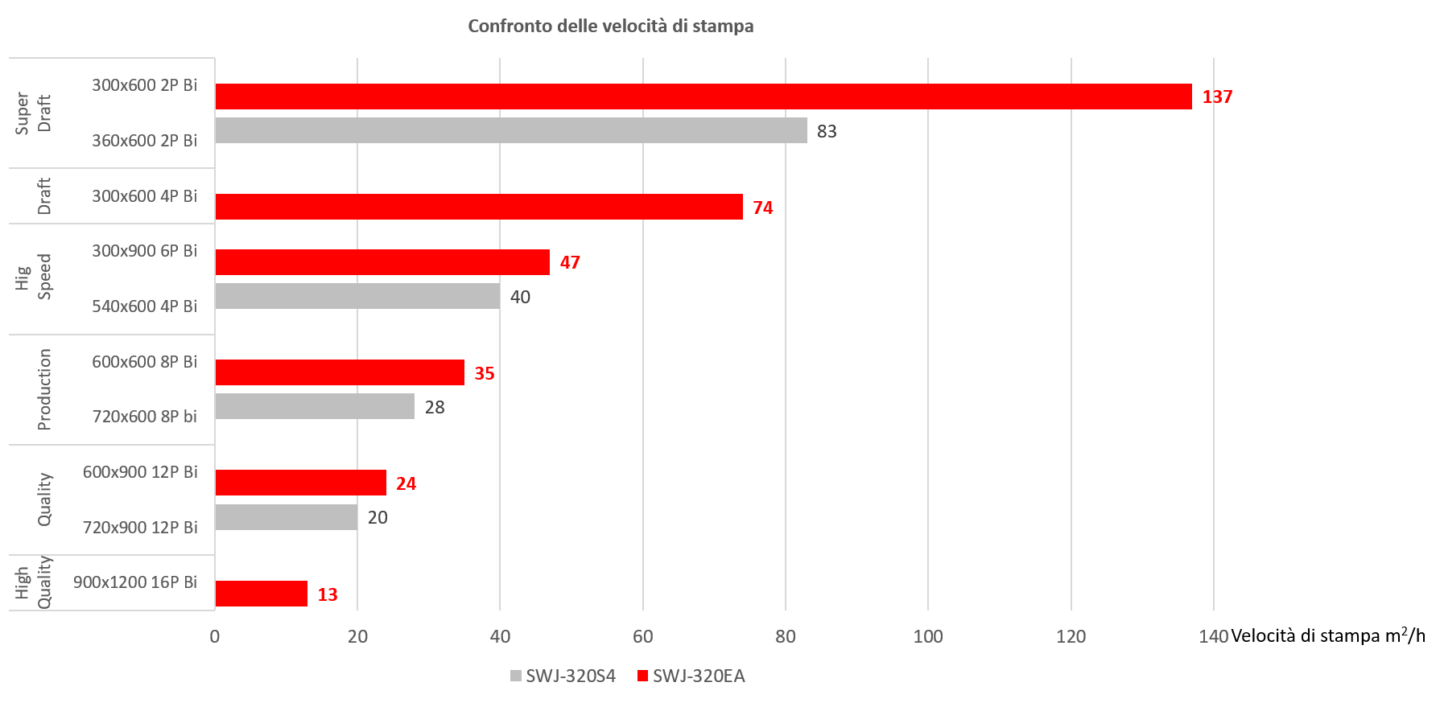

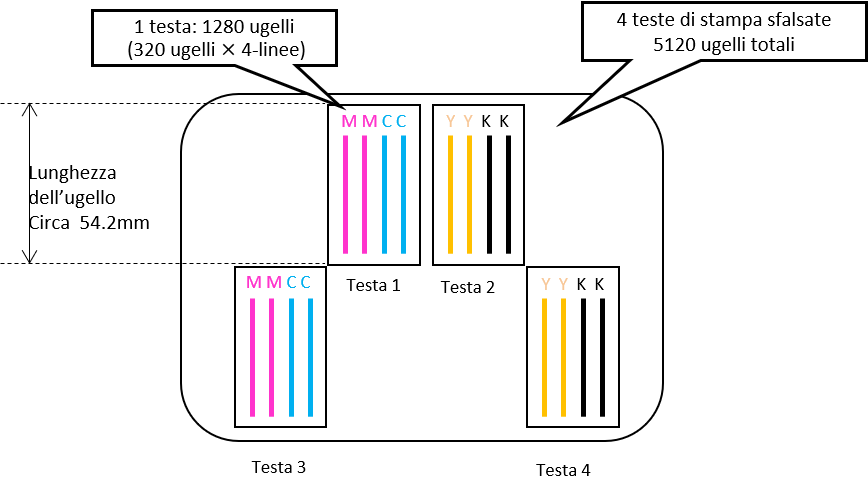

A successor to the legendary SWJ-320S4, the Mimaki SWJ-320EA is a revolutionary 3.2-meter-wide solvent printer with new-generation high-speed print heads arranged in a staggered mode, making it possible to print large-format images for almost any outdoor or indoor purpose. Its functionality is expanded by Mimaki Core Technologies, including MAPS4 and NRS, offering a unique combination of affordability, high quality and reliability.

SUPER WIDE FORMAT SOLVENT-BASED HIGH QUALITY AND SPEED UP TO 137M2/H

Mimaki SWJ-320EA is the innovative super wide format printer with solvent technology characterized by excellent production performance and a very advantageous quality-price ratio.

Featuring a span of up to 3.2 metres, the SWJ-320EA features all of Mimaki’s core technologies, including MAPS4 (Mimaki Advanced Pass System) and the NRS nozzle recovery system to offer an unparalleled relationship between price, quality and reliability.

Mimaki SWJ-320EA

ADVANTAGES

For even more confidence, our products are GREENGUARD GOLD certified.

GREENGUARD GOLD certified products meet strict standards regarding low volatile organic compound emissions and reinforce that the product is suitable for use in places such as schools and health centers, without polluting indoor air quality.

Mimaki SWJ-320EA

SPECIFICATIONS

Mimaki SWJ-320EA

CORE TECHNOLOGY

This printer features advanced Mimaki technology that delivers the best print quality, maximum productivity and reduced exposure to the risk of production delays. See below for a list of the SWJ-320EA’s technological features.

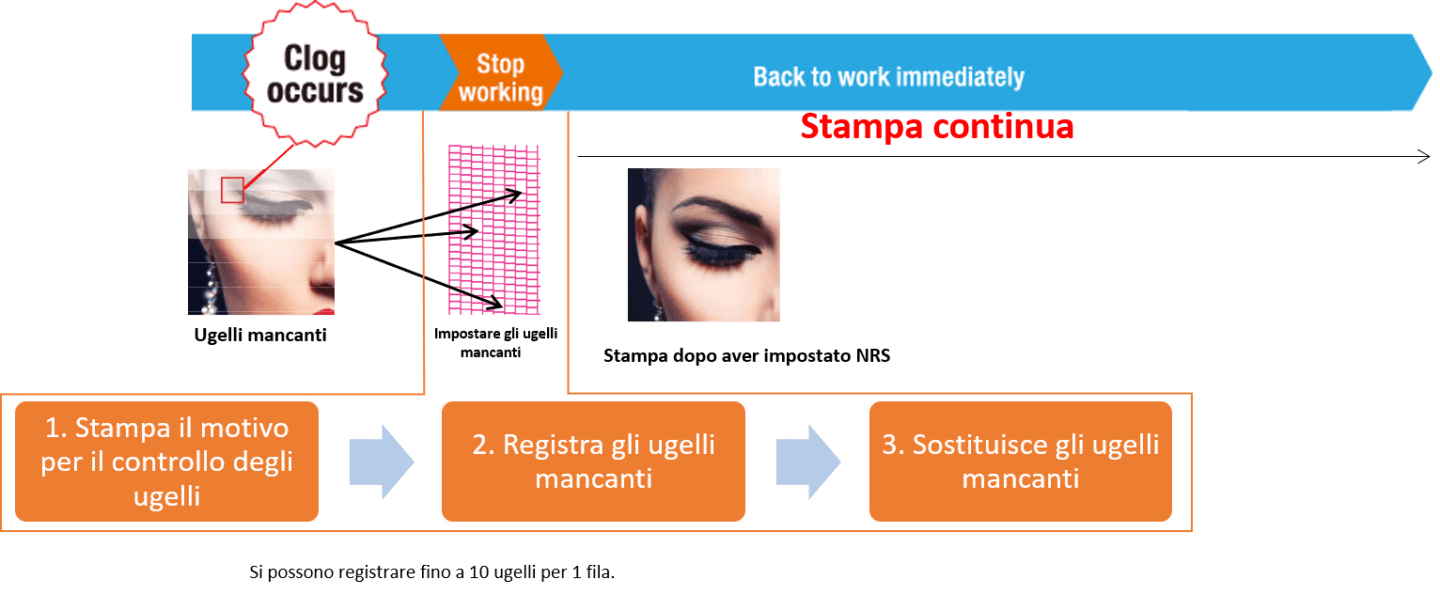

Nozzle Check Unit

This technology controls the printing nozzles and automatically activates a series of recovery functions, ensuring printing quality and avoiding waste.

Nozzle Recovery System

This technology automatically assigns operational nozzles when an interruption is detected, giving you the assurance that your production and costs will not be affected.

Mimaki Circulation Technology

MCT is a function that prevents pigment sedimentation by periodically circulating the ink in its ink channel, reducing maintenance costs and increasing productivity.

Automatic Cleaning Function

To keep the print head clean at all times

Automatic Wiper Cleaner

To keep the cleaning system equally clean

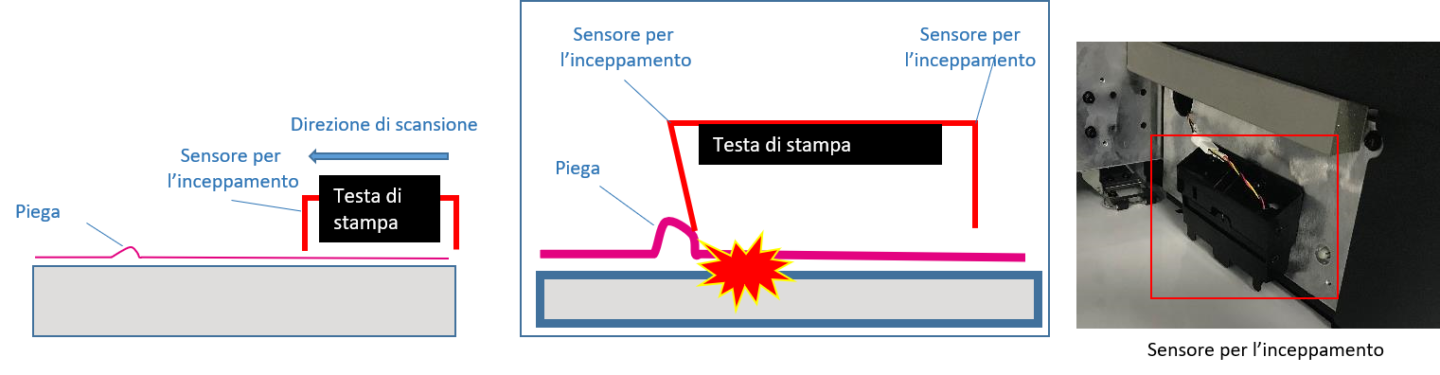

Jam Sensor

This function that prevents the print head damage. Reducing maintenance costs and increasing productivity.

Mimaki Advanced Pass System

Mimaki’s exclusive Advanced Pass System technology uses an advanced algorithm that reduces banding, allowing high print quality even at higher speeds.

Waveform Control

WFC automatically switches the signal to the print head when printing conditions change and ensures consistent image quality.

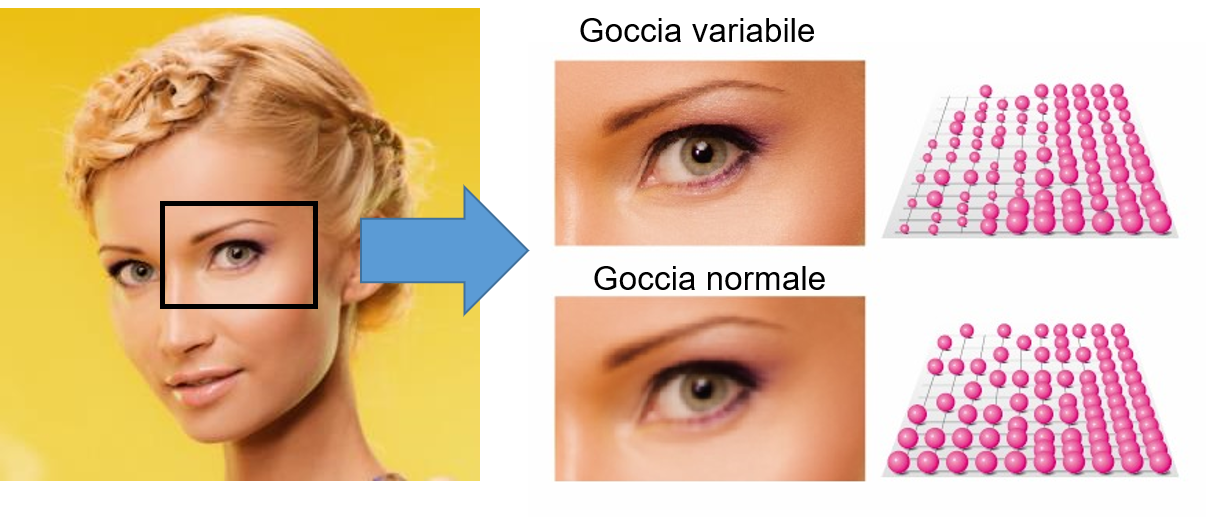

Variable Dot Technology

VDT is a feature of the piezo print head that allows the creation of ink droplets of different sizes, allowing for smoother gradations and greater detail.

Mimaki Fine Diffusion

For softer colors