3DUJ-553

Mimaki 3DUJ-553

The world’s first UV-curable

color 3D inkjet printer

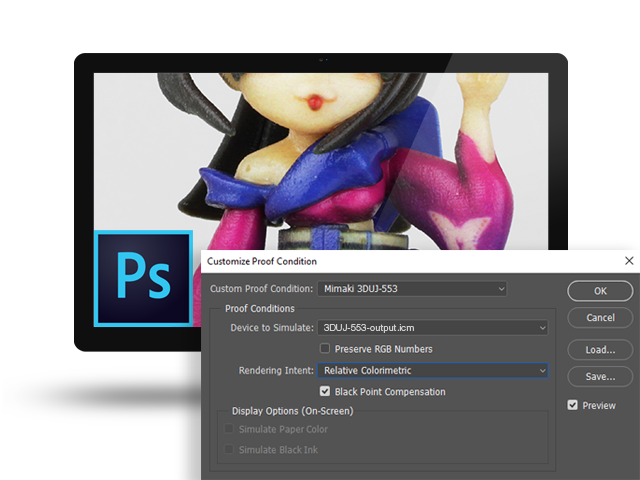

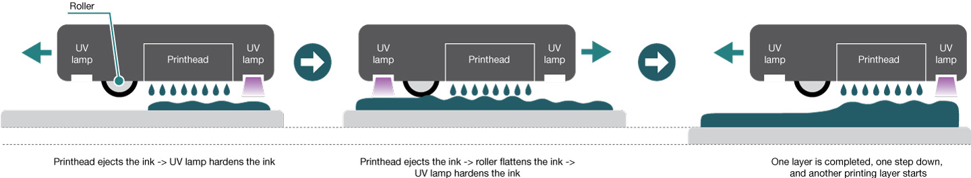

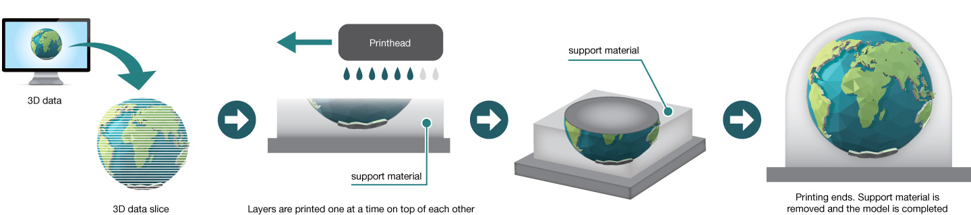

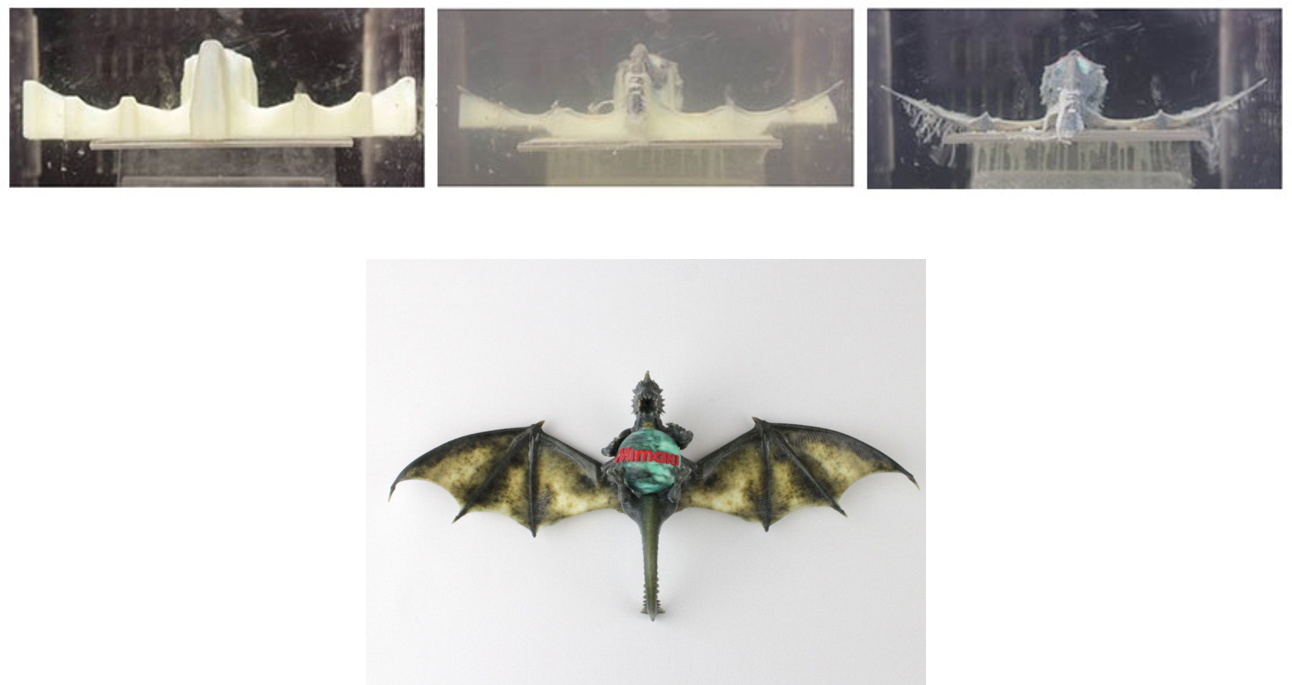

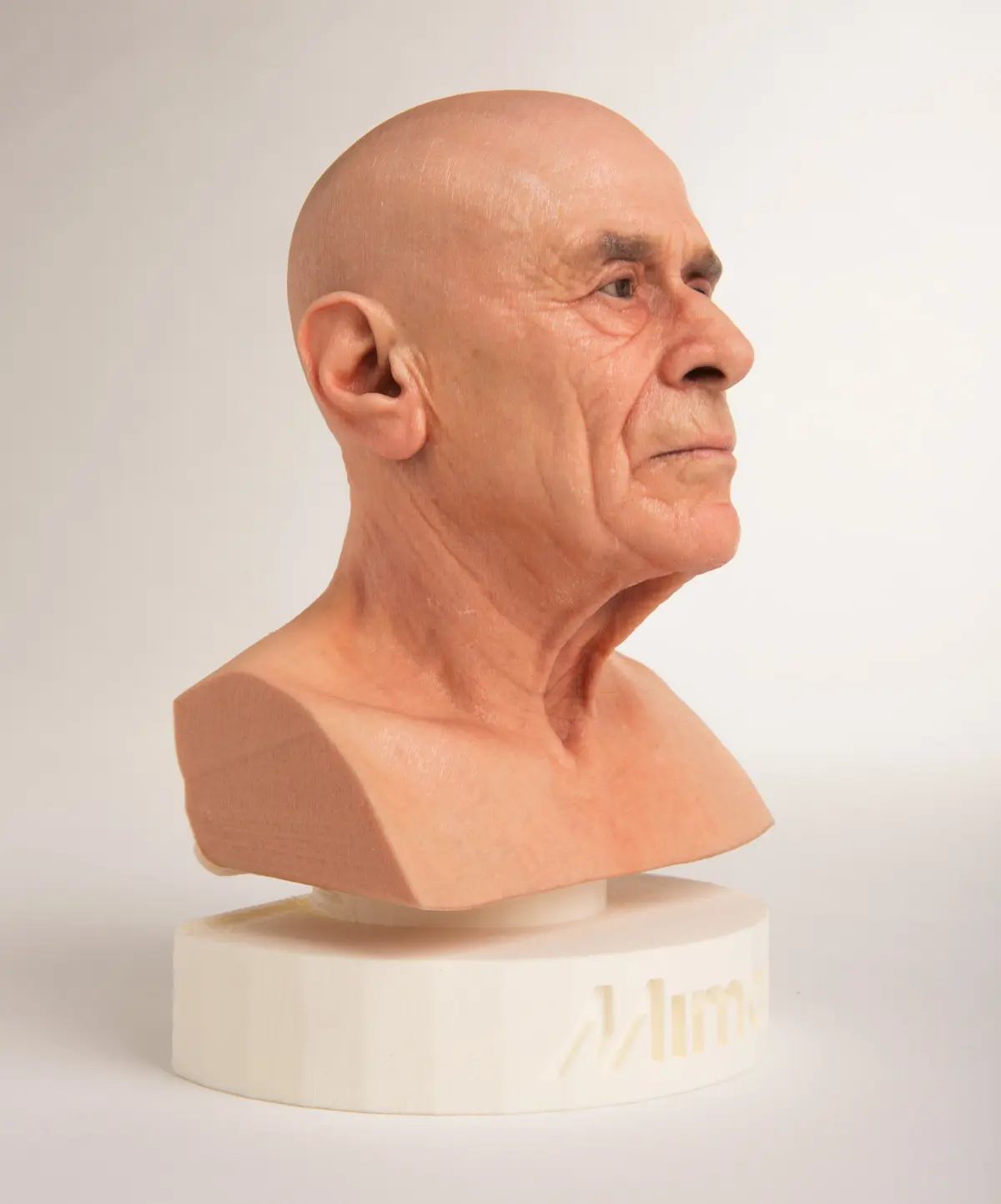

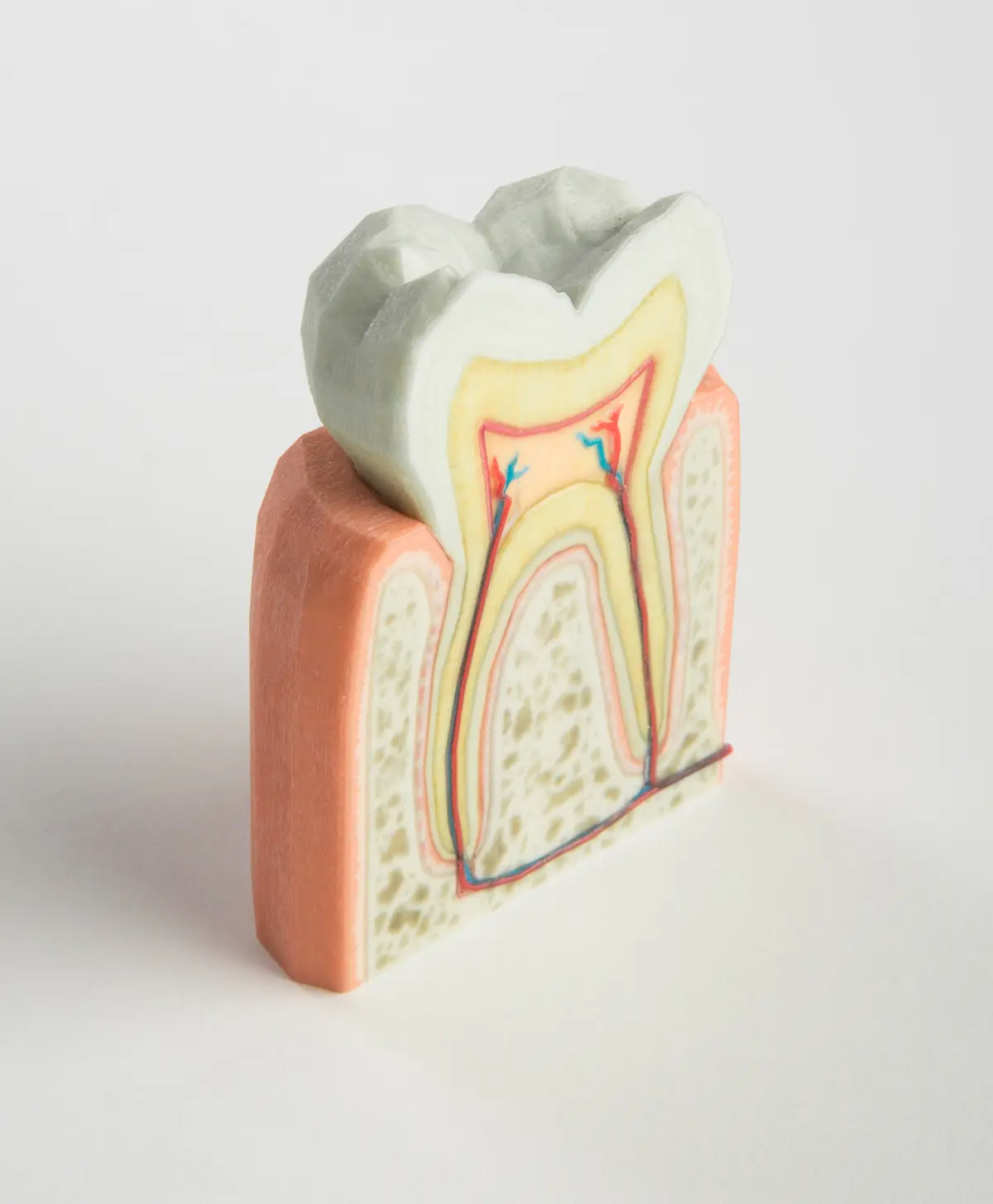

The Mimaki 3DUJ-553 is the first 3D solution to print with over 10 million colors, enabling photorealistic creation of signage, prototypes, parts, products and other 3D applications that previously required separate painting. With the UV LED curing method, objects can be printed in layers and a UV ink finish of approximately 22 microns applied using CMYK colors and varnish, producing a quality finished object.

The Mimaki 3DUJ-553 printer features fast start-up times and minimal energy usage, reducing overall running costs.

Full color UV LED 3D printer with photoREALISTIC quality

The Mimaki 3DUJ-553 offers the world’s first 3D modeling with over 10 million color combinations, covering approximately 84% of the FOGRA39L and 90% of SWOP color gamuts. With layer thickness as fine as 19 μm, the printer produces smooth and visually stunning 3D models.

The unique features of the Mimaki 3DUJ-553 enable the creative production of durable objects up to 50 x 50 x 30 cm in size. The printer also features fast start-up times and low energy consumption, helping to reduce overall operating costs.

Mimaki 3DUJ-553

ADVANTAGES

For even more confidence, our products are GREENGUARD GOLD certified.

GREENGUARD GOLD certified products meet strict standards regarding low volatile organic compound emissions and reinforce that the product is suitable for use in places such as schools and health centers, without polluting indoor air quality.

Mimaki 3DUJ-553

Create the future in color!

Mimaki 3DUJ-553

SPECIFICATIONS

Mimaki 3DUJ-553

CORE TECHNOLOGY

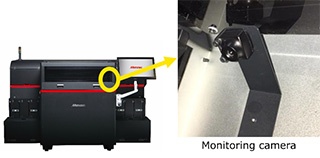

This printer features Mimaki Core Technologies that deliver the best print quality, maximum productivity, and reduced exposure to risks that can delay production. Below is a list of the core technologies included in the 3DUJ-553.

Nozzle Check Unit

This technology controls the printing nozzles and automatically activates a series of recovery functions, ensuring printing quality and avoiding waste.

Waveform Control

WFC automatically switches the signal to the print head when printing conditions change and ensures consistent image quality.

Variable Dot Technology

VDT is a feature of the piezo print head that allows the creation of ink droplets of different sizes, allowing for smoother gradations and greater detail.