UJF-7151 plusII e

Mimaki JFX200-2513 EX

Challenges in the Industrial Printing Market and New Solutions Offered by the New Model

The proliferation of digital printing has normalized short-run, multi-variety production in custom goods printing sector, such as smartphone cases, promotional items, and character goods. In the industrial printing sector, inkjet printers capable of stable printing on diverse materials like metal and resin are increasingly being adopted.

UJF-7151 plusII e

Addressing these challenges, the new UJF-7151 plusII e model inherits the top-class printing precision and productivity highly praised in previous models while significantly enhancing ink layering capability and uneven surface adaptability. Building on its existing performance printing on thick materials, it now enables three-dimensional texture expression through ink layering and improved conformability to diverse shapes like curved surfaces and irregularities. This supports high-value-added manufacturing across a wide range of fields, including custom goods businesses and industrial printing, opening new possibilities for industrial printing.

・Custom Goods Printing: Enhances the added value and brand expression of customized products through three-dimensional texture printing.

・Industrial Printing: Supports manufacturing efficiency and new market development through stable printing on stepped and curved components

Mimaki JFX200-2513 EX

ADVANTAGES

For even more confidence, our products are GREENGUARD GOLD certified.

GREENGUARD GOLD certified products meet strict standards regarding low volatile organic compound emissions and reinforce that the product is suitable for use in places such as schools and health centers, without polluting indoor air quality.

Mimaki JFX200-2513 EX

SPECIFICATIONS

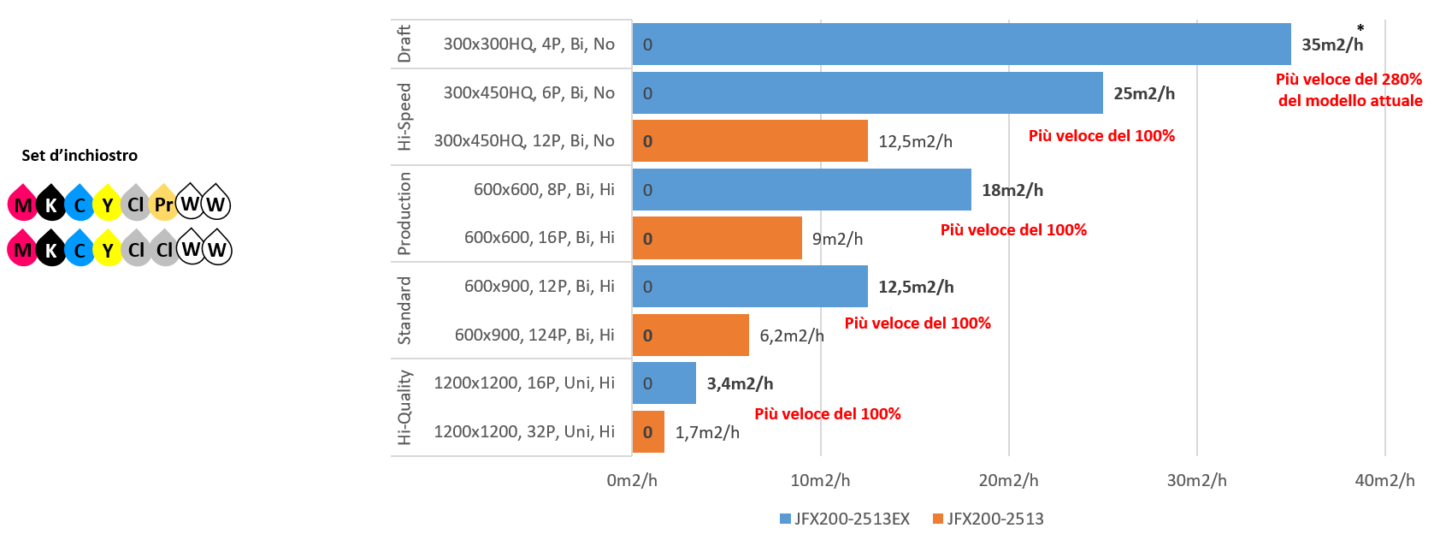

Productivity and Convenience

PRINT QUALITY

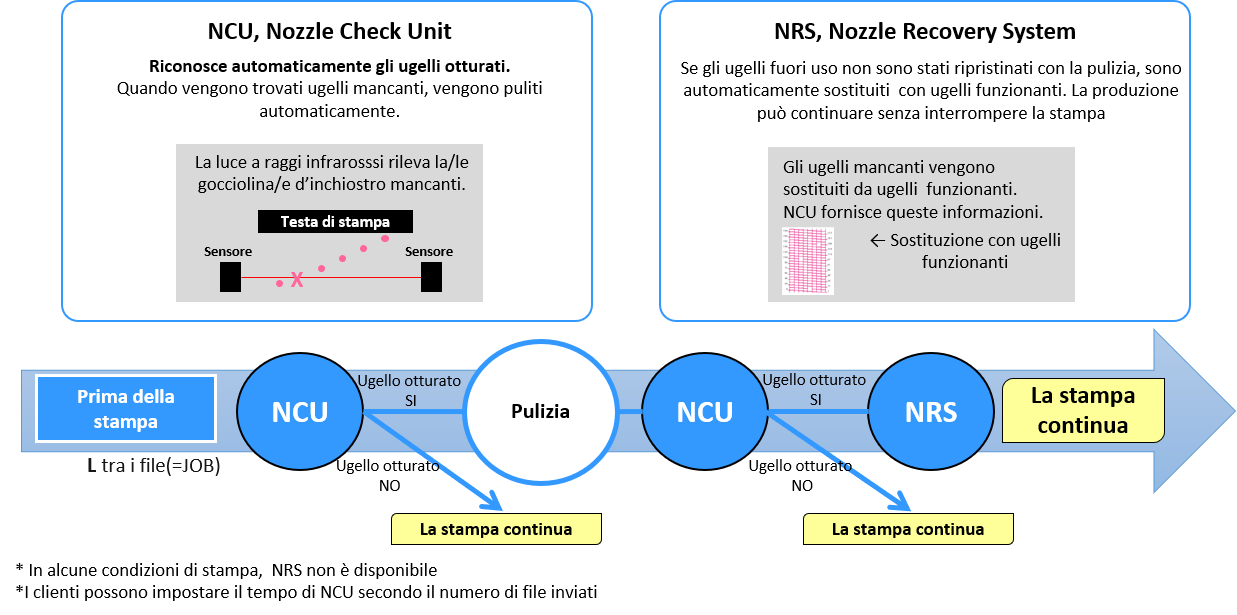

Nozzle Check Unit

This technology controls the printing nozzles and automatically activates a series of recovery functions, ensuring printing quality and avoiding waste.

Nozzle Recovery System

This technology automatically assigns operational nozzles when an interruption is detected, giving you the assurance that your production and costs will not be affected.

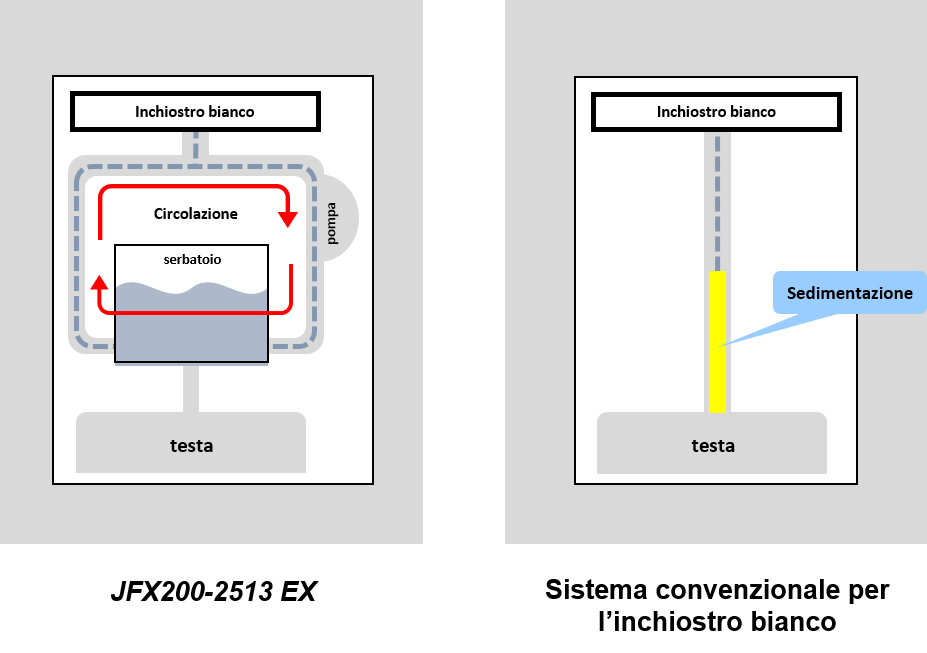

Mimaki Circulation Technology

MCT is a function that prevents pigment sedimentation by periodically circulating the ink in its ink channel, reducing maintenance costs and increasing productivity.

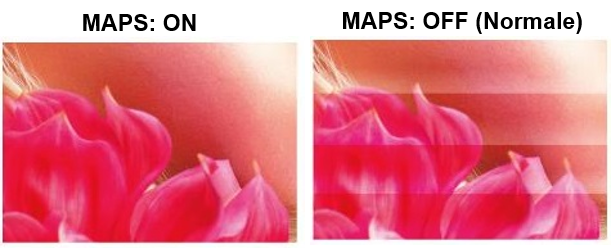

Mimaki Advanced Pass System

Mimaki’s exclusive Advanced Pass System technology uses an advanced algorithm that reduces banding, allowing high print quality even at higher speeds.

Waveform Control

WFC automatically switches the signal to the print head when printing conditions change and ensures consistent image quality.

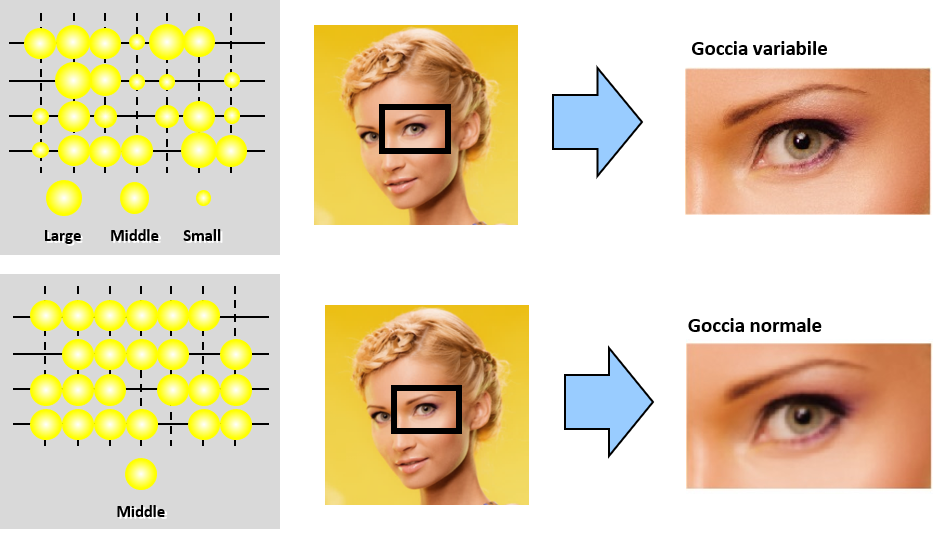

Variable Dot Technology

VDT is a feature of the piezo print head that allows the creation of ink droplets of different sizes, allowing for smoother gradations and greater detail.